5. Shipping marks as per request.

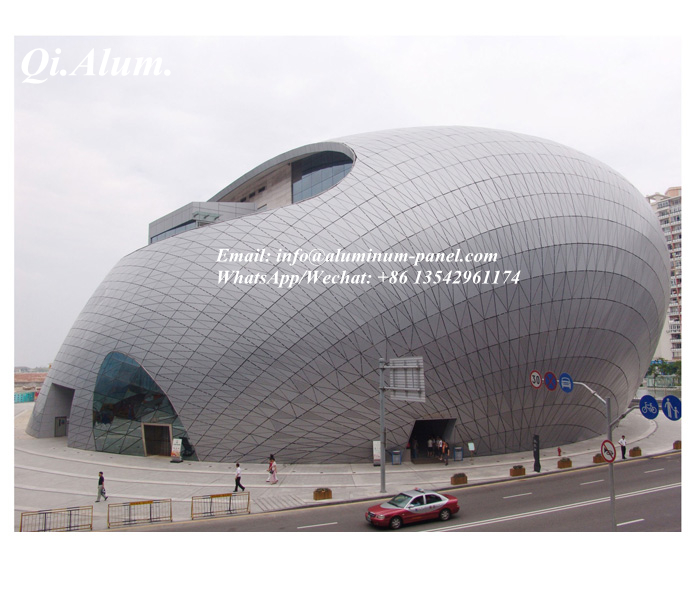

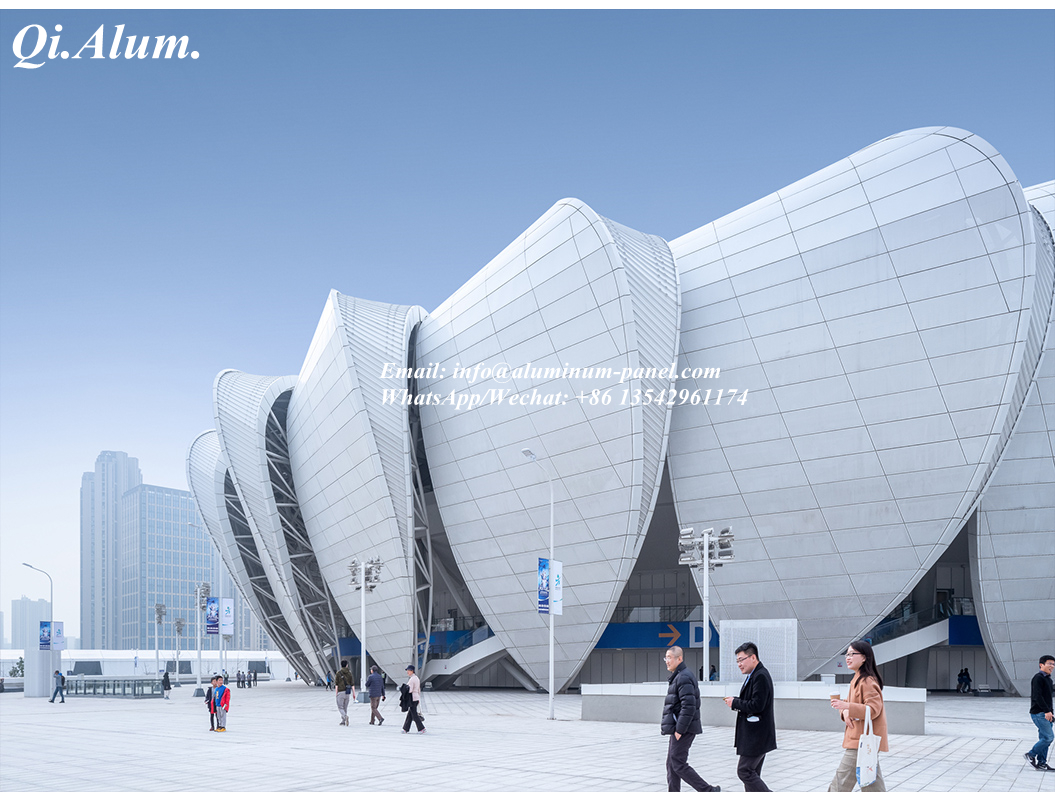

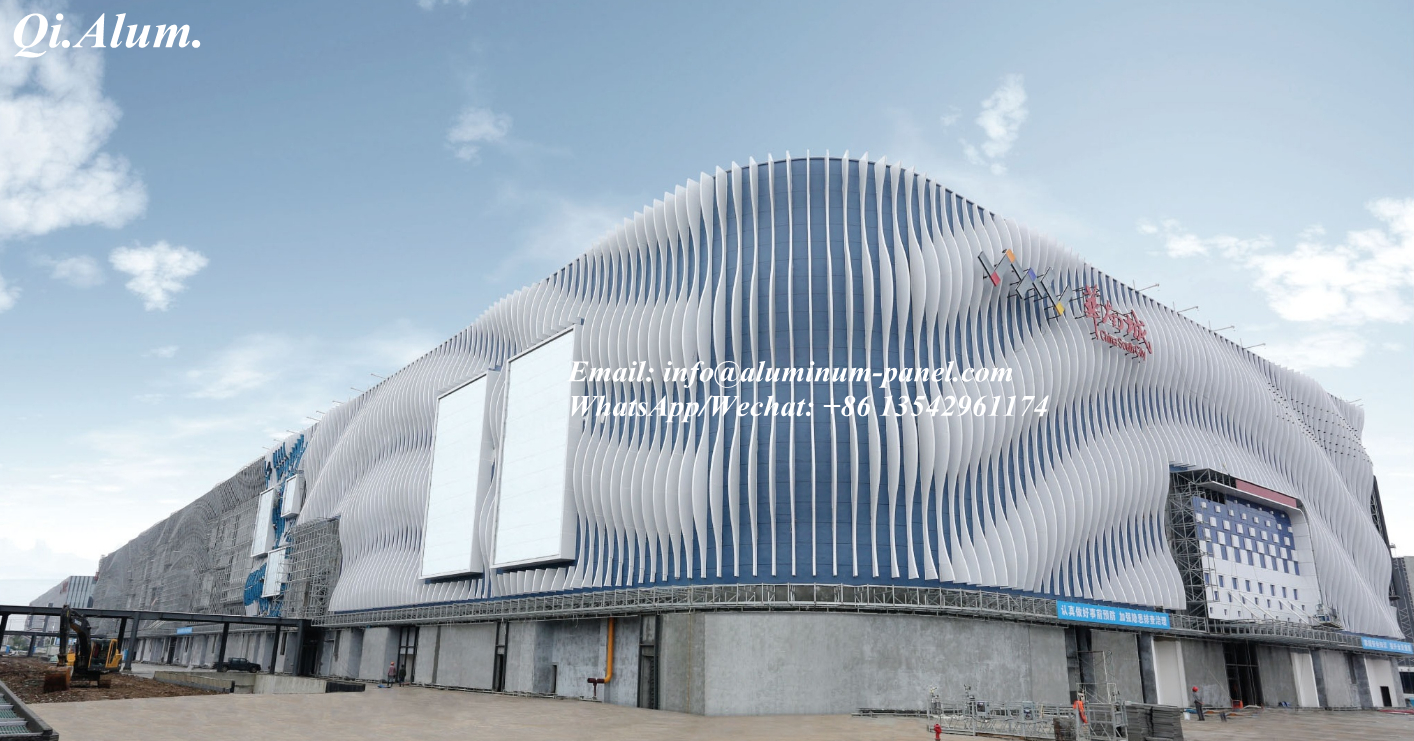

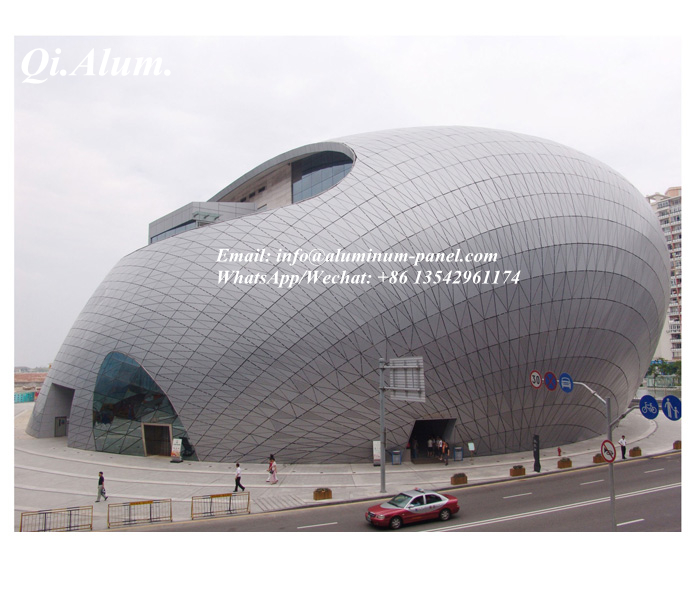

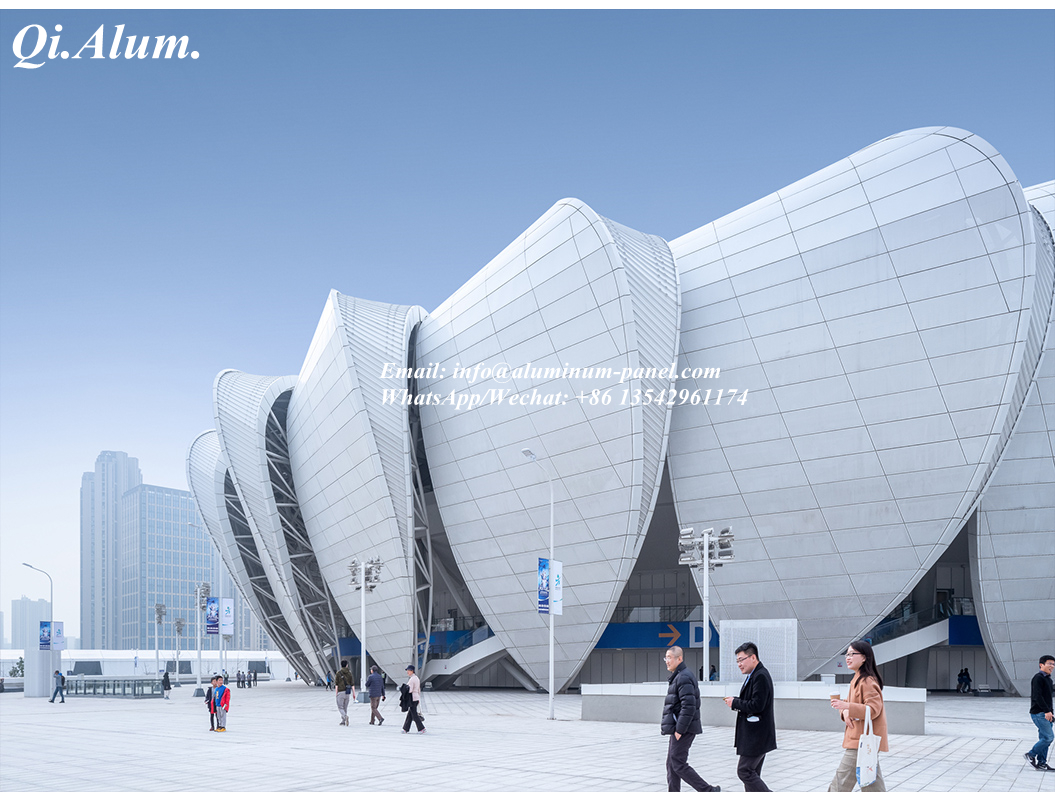

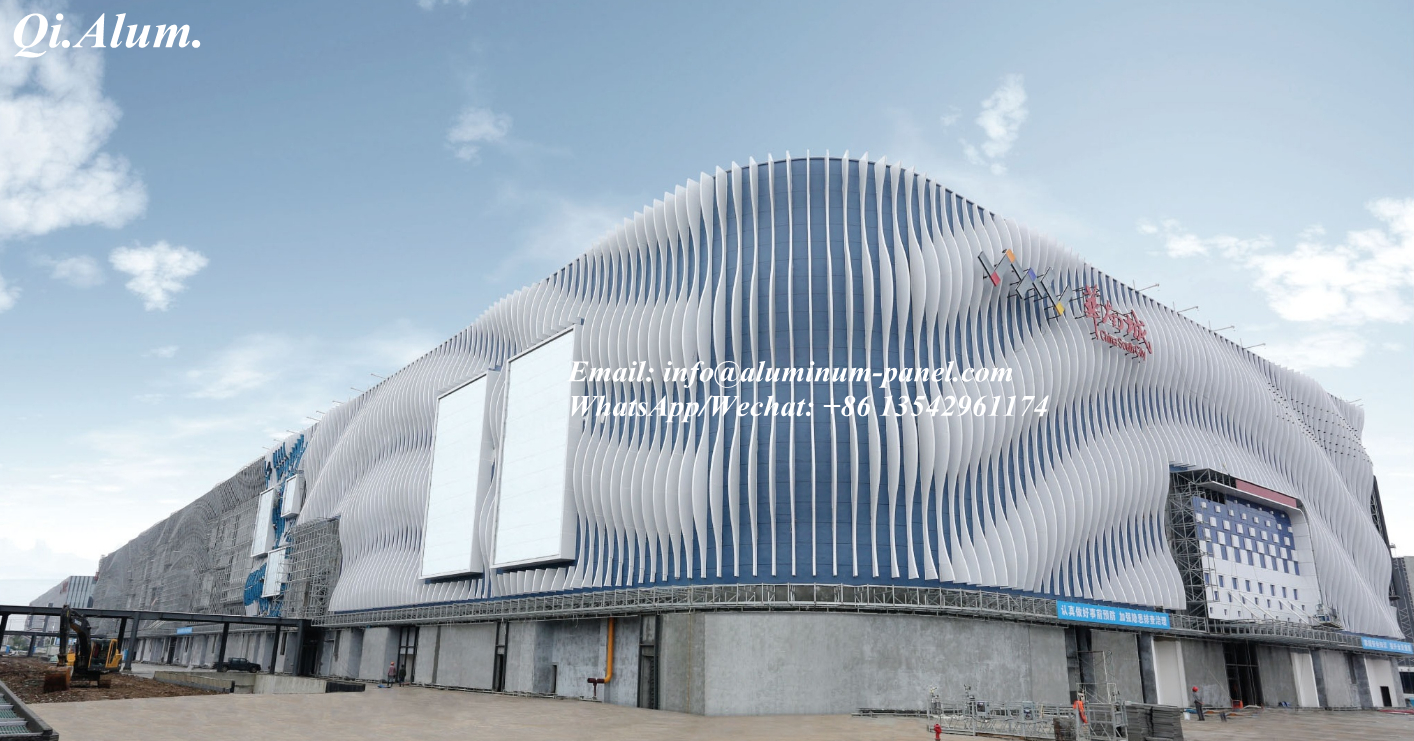

Project case

FOSHAN QI ALUMINUM DECORATIVE MATERIALS CO.,LTD

Shiquan Tiekeng Industrial, Nanhai Area, Foshan, Guangdong Province, China

0086 13542961174

info@aluminum-panel.com

0086 13542961174

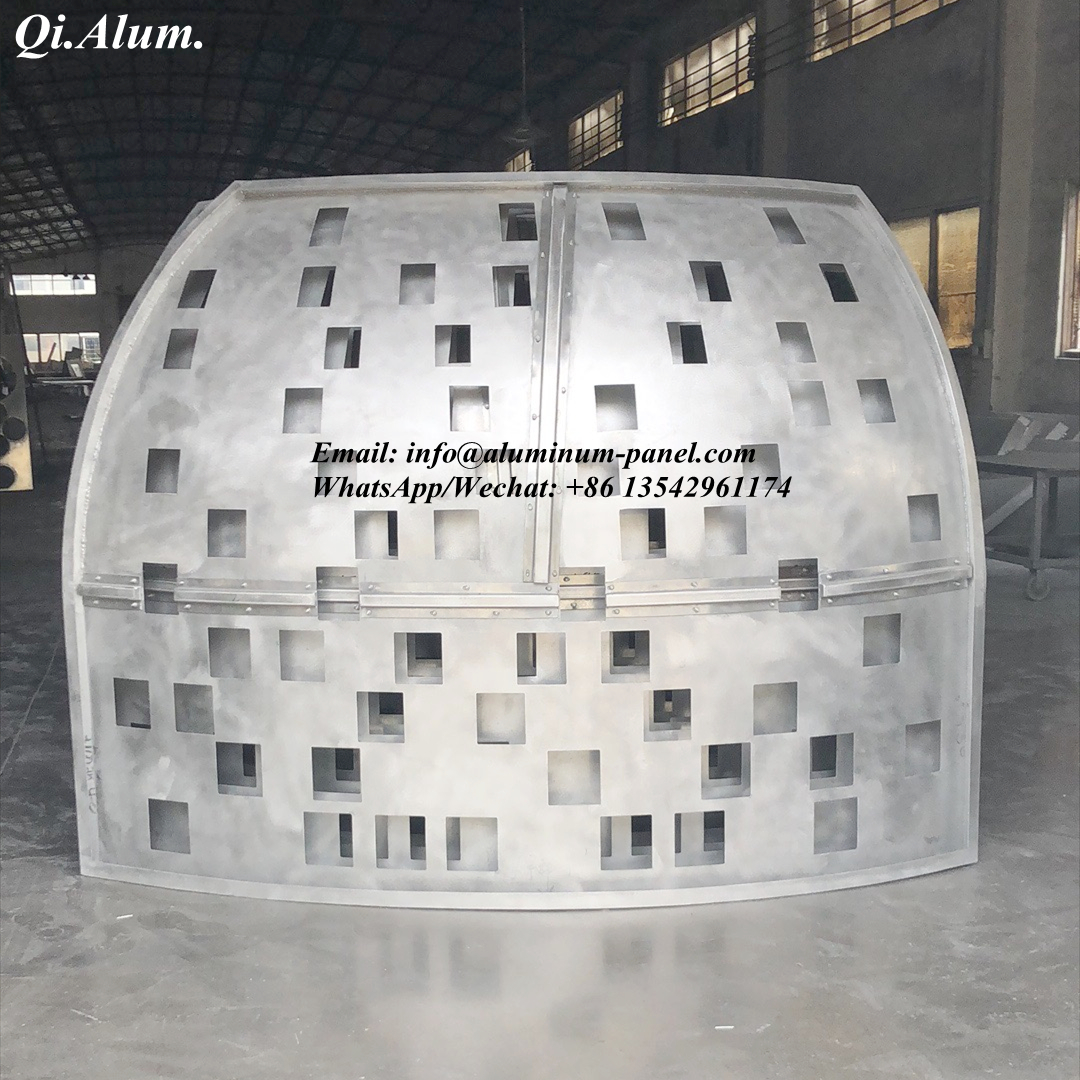

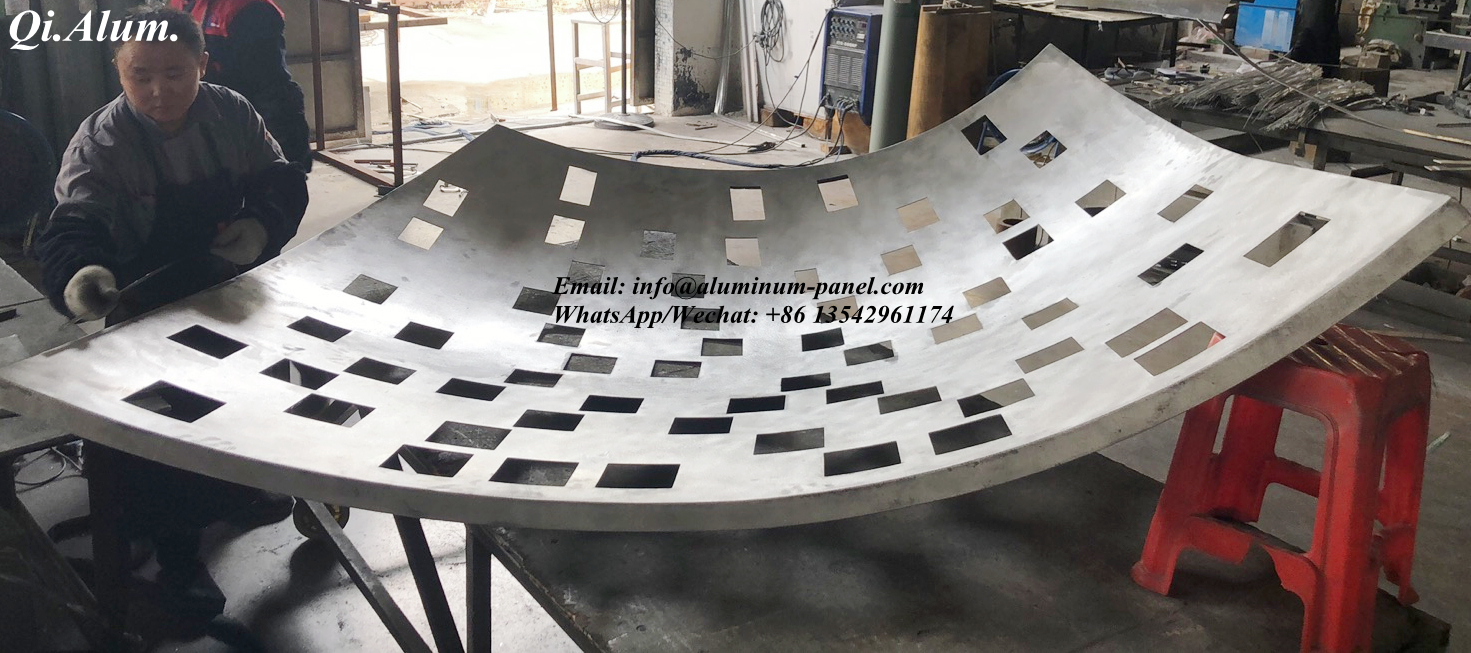

1, aluminum double curved panels is made of high quality aluminum alloy, after fine processing, so the service life of aluminum double curved panels is long, which saves the cost to a certain extent. 2, aluminum hyperbolic plate has good air tightness, which is very important to the curtain wall. Usually, there are three kinds of sealing methods of aluminum panel, which are internal waterproof, glue sealing and structural waterproof. Usually, aluminum double curved panels adopts the internal structure waterproof, and disturb the sealing treatment, so as to ensure the waterproof performance of aluminum double curved panels to a greater extent. 3, in the aluminum double curved panels surface can also be sprayed with various colors of paint, with color to further enhance the visual impact. In addition, different from the conventional shape of aluminum panel, aluminum double curved panels production is more difficult, the accuracy of the machine and the operation of technical workers have higher requirements. Therefore, aluminum double curved panels has a strong technical content. 4, aluminum double curved panels has good appearance display effect. Although the production process is relatively troublesome, the existence of aluminum double curved panels creates a personalized architectural style, thus expanding the design space of the architect, showing the irreplaceable charm of aluminum double curved panels on the metal curtain wall. 5,Aluminum double curved panels due to light weight, good rigidity characteristics, so can create a multi-level space, but also can design a variety of different colors, applied in more buildings. Usually, it is widely used in outdoor columns, curved or spherical building curtain walls and other decoration.

Aluminum Double Curved Panels is mainly the use of high strength aluminum alloy plate as the substrate, thickness between two to four millimeters, size and specification flexibility, can choose more categories. Aluminum Double Curved Panels in the processing of the back will be added to strengthen the ribs, so that the hyperbolic aluminum veneer in the vertical plate load is able to fix the stress around the distribution, strengthen the bearing capacity and stability of aluminum panel, but also strengthen the strength and thickness of aluminum panel. This provides a good material choice for designers to apply aluminum panel materials.

Application of aluminum double curved panels:

Lightweight, good rigidity and intensity.

Good weather ability and great corrosion resistance.

Easy for processing. It can be formed into different forms, such as the cambered plane, or spherical plane after processing and coating.

Coating uniform, varied color choices.

Sound insulation and heat insulation.

Strong earthquake resistance and fireproof.

Not easy to stain, convenient to clean and maintain.

Easy to install and cost-effective.

Recyclable, friendly to the environment.

details

5. Shipping marks as per request.

Project case